Solar energy is rapidly becoming a cornerstone of our sustainable future. However, the process of designing a solar system, particularly the intricate task of stringing them together, can be time-consuming and labour-intensive. Introducing auto-stringing, a game-changing feature that automates the design process of connecting solar panels in series to form strings to ensure optimal energy production, saving time and resources for solar designers. With this revolutionary innovation, efficiency meets precision like never before.

What is Auto-stringing?

Traditional manual stringing is a time-consuming process that relies heavily on human labor and is prone to errors. Auto stringing revolutionizes this by using advanced automation to seamlessly connect solar panels in series, optimized for production and efficiency.

Why Auto-stringing is impactful for string inverter-based systems?

Auto-stringing is designed to optimize solar system layouts that utilize string inverters, where multiple panels are connected in series to form a ‘string.’ The advanced algorithms determine the ideal number of panels per string, maximizing energy output while ensuring compliance with inverter voltage and current limits. In contrast, microinverter-based systems eliminate the need for complex stringing calculations, as each panel operates independently with its own dedicated inverter.

Auto-stringing working mechanism:

Auto-stringing employs a sophisticated multi-step process to ensure maximum efficiency and accuracy in solar designs.

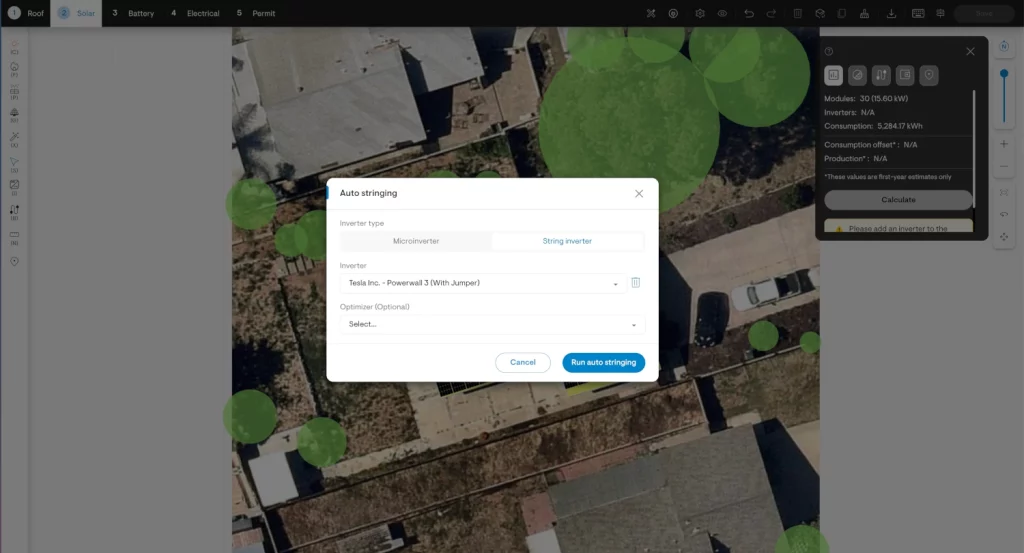

- Data input & validation: The process begins with inputting critical data like panel, inverter, and optimizer details. Auto-stringing then performs electrical validations such as voltage, current, power, etc. to ensure components are fully compatible.

- System evaluation: Based on the selected components and project parameters, auto-stringing generates a vast array of possible system configurations. This involves exploring multiple factors like panel location, string direction distance between panel arrays, pitch and azimuth, various combinations of panel strings, inverter configurations, and MLPE arrangements.

- Optimization: Utilizing advanced optimization techniques such as Grouping, Computational Geometry, Combinatorial Optimization, Resource Allocation & Numerical Optimization techniques, auto-stringing finds the best-performing system design and minimizes costs while still being installation-friendly. The primary objective is to minimize system costs and wire lengths by creating balanced strings. For inverter systems with MPPTs (Maximum Power Point Trackers), it groups panels into series-connected strings, each connected to an inverter’s MPPT input considering factors such as the number of MPPTs, number of DC inputs per MPPT slot. This step ensures the most efficient and cost-effective design for the system

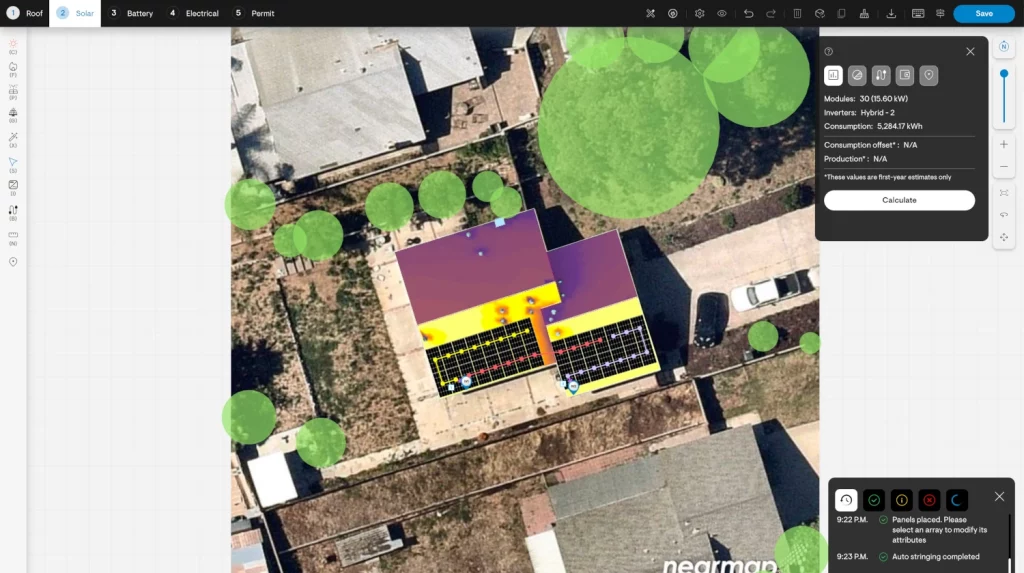

- Design output and visualization: The final stage involves generating a comprehensive output, including number of inverters and their associated string configurations and locations. This data is then utilized to create a graphical representation of the solar panel layout for user to visualize the design within the tool.

Advantages of auto-stringing for installers

Solargraf takes auto-stringing a step further by integrating this advanced capability into an intuitive, user-friendly platform. With just a few clicks, installers can generate optimized string layouts, ensuring compliance with electrical constraints while maximizing efficiency.

By leveraging advanced algorithms, Solargraf’s auto-stringing feature empowers designers to:

- Achieve optimal system performance: Auto-stringing meticulously analyzes a multitude of variables, such as panel specifications, inverter and optimizer details, and site-specific data, to determine the most efficient stringing configurations. This optimization process not only maximizes energy output and minimizes energy losses but also ensures the system operate at its full potential, delivering optimal performance every time.

- Accelerate design time: Manual design processes can be incredibly time-consuming specially for large systems. Auto-stringing cut down this time drastically, deliver results in less than a second and allows designers to focus on other higher-level tasks.

- Reduce costs: By optimizing number of strings and string lengths, auto-stringing helps to reduce overall project costs. This translates to significant savings for both installers and homeowners, making solar energy more accessible and affordable.

- Enhance design accuracy: Human error is a common challenge in manual design processes. Auto-stringing eliminates this risk by performing precise electrical calculations and adhering to strict structural design guidelines. This ensures that every system is designed with accuracy and reliability.

Auto-stringing is a powerful feature that simplifies the complexities of solar system design while ensuring optimal performance, efficiency, and cost savings. By leveraging advanced algorithms and automation, Solargraf reduces manual labor, minimizes errors, and accelerates the design process, empowering solar designers to focus on higher-level tasks. Whether you’re working with large-scale systems or fine-tuning configurations for maximum energy output, auto-stringing ensures faster, more accurate, and scalable solutions.

Schedule a demo today if you want to know more about this revolutionary feature!

United States

United States Germany/Austria

Germany/Austria Brazil

Brazil Netherlands

Netherlands Japan

Japan